After the war all the aircraft and military contracts were cancelled and Wellworthy was left with very little. Sales had fallen by 55% in 1946 and the labour force was reduced to 2,500. However, Howlett returned to producing piston rings and other components for private cars. Sales began to increase, helped by a growing demand for diesel engines and gas turbines.

By 1951 sales had reached the peak wartime level of just over £2m and by the mid-1950s half a million piston rings were being produced every week. The company was also investing significantly in research, and by 1956 held over 100 patents. In order to meet this demand, a new factory was purchased at Bridgewater in Somerset in 1961, and another in Weymouth in 1966. This growth continued in the 1960s, with pistons taking over from piston rings as the most important product. While some products, such as aircraft pistons, largely disappeared from the Wellworthy range, other new products took their place. By 1968 the company was also producing cylinder liners, valve seat inserts, gudgeon pins, powder handling air compressors and a jointing compound known as Wellseal.

By the 1970s Wellworthy was again employing over 5,000 people and was renowned throughout the world for its quality products, technical know-how, research and development and ‘after supply’ help. They produced about 2,000 variations of products supplying aircraft, tanks, petrol engines, diesel engines, compressors and pit pumps, among others. This growth continued into the 1980s, but with the market shrinking and more people made redundant every year, the end was in sight.

The Stanford Road factory was the first to close, in 1981, with all production moved to Ampress. Then in early 1988 all small piston manufacturing was transferred from Lymington to Bridgewater. By December the Heavy Piston machining facility was moved to Birmingham and piston ring manufacture was transferred to Ringwood. Finally, in 1989, following a takeover by the American company Federal Mogul, the Wellworthy works at Ampress were closed down. The Advertiser & Times summed up the position poignantly on 7 October 1989:

This is a sad week indeed for Lymington, as the last remnants of the Wellworthy piston firm finally vacated the town of its birth… Since the recession of the early ‘eighties, and take-over bids by larger groups … in the end, just 40 employees were transferred to the Ringwood branch and four to Bradford in Yorkshire. The remainder were made redundant or took early retirement.

The gallery below shows images of the post war years at Wellworthy.

An aerial view of the Wellworthy factory LMGLM:2011.1.3

Wellworthy employees working in the piston room

Wellworthy employees working in the factory

Two women making pistons at Wellworthy

Drivers with Wellworthy delivery vans LMGLM: 2011.1.15

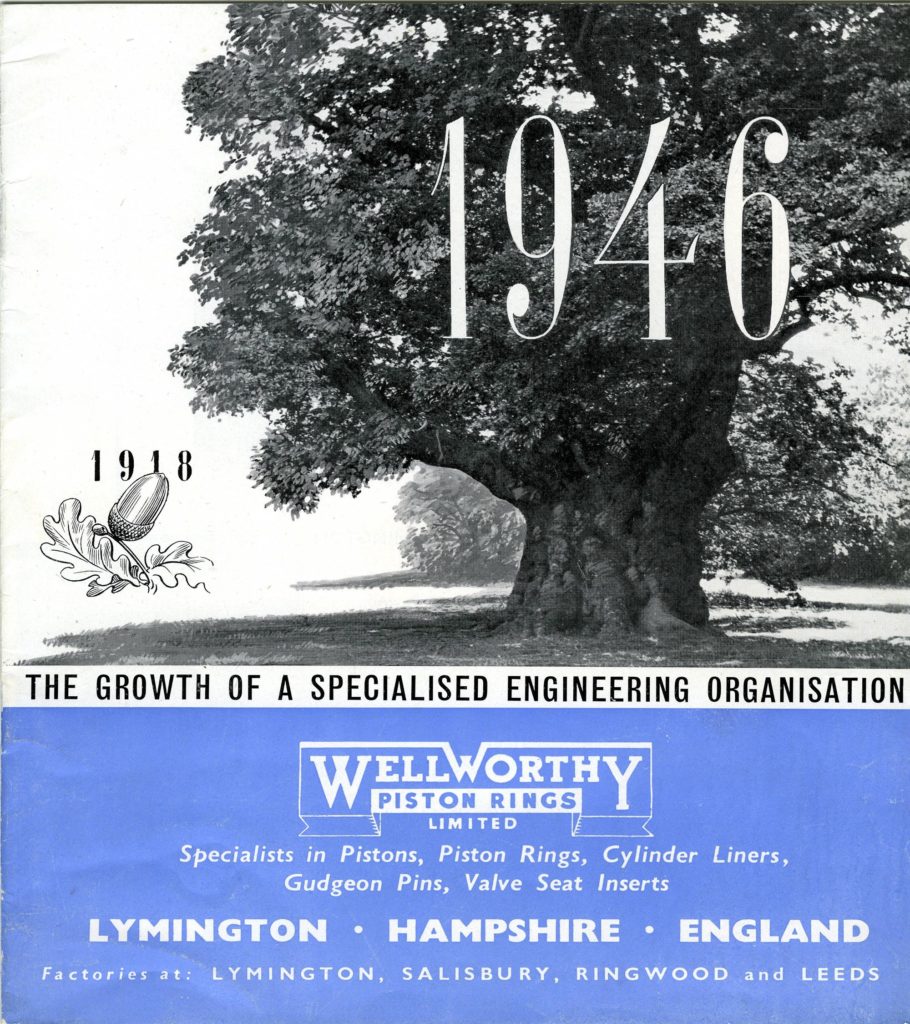

Cover of the Wellworthy magazine the ‘Acorn’ in 1946

The Sand Foundry in 1955. “In the 50s, office staff were required to work a 37½ hour week, while shop floor workers did a 44 hour week. Apprenticeships were much sought after: indentures were for five years and you went to Technical College and did training on the job, and moved on every six months to a new department. You were expected to be at your post when the bell rang at 7.30am until 10 o’clock when there was a paid break of 10 minutes, again timed by the bell.” Wilf Adams

The ‘Wellworthy graveyard’, commemorating the loss of different factories. This was planted in a patch of earth on the factory floor where two huge squeeze casting machines once stood.